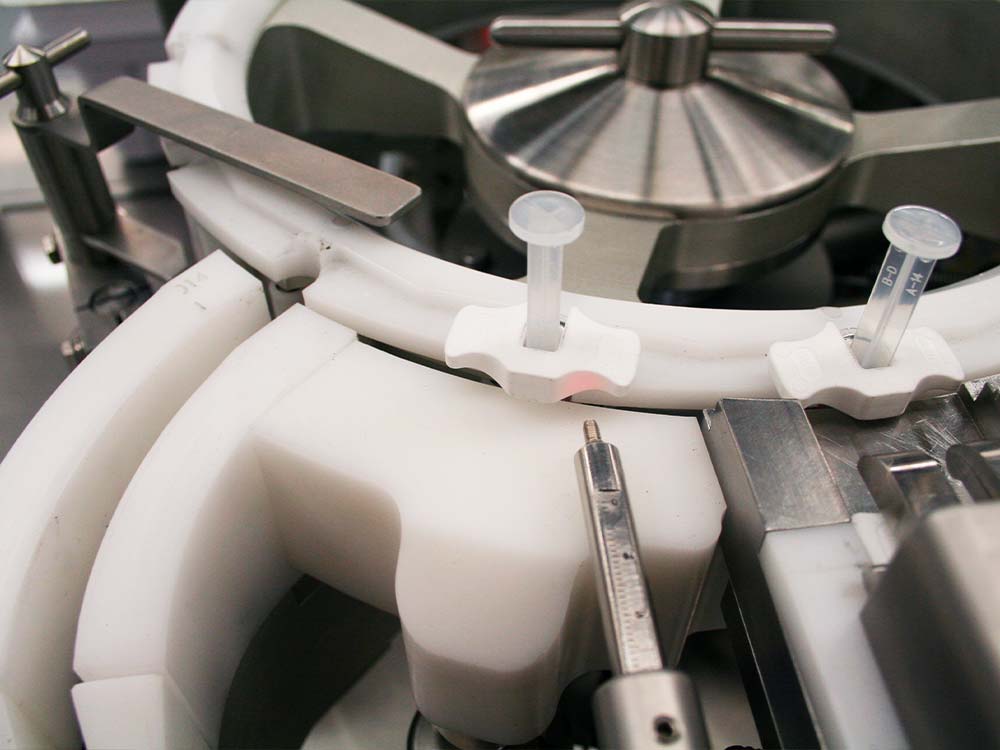

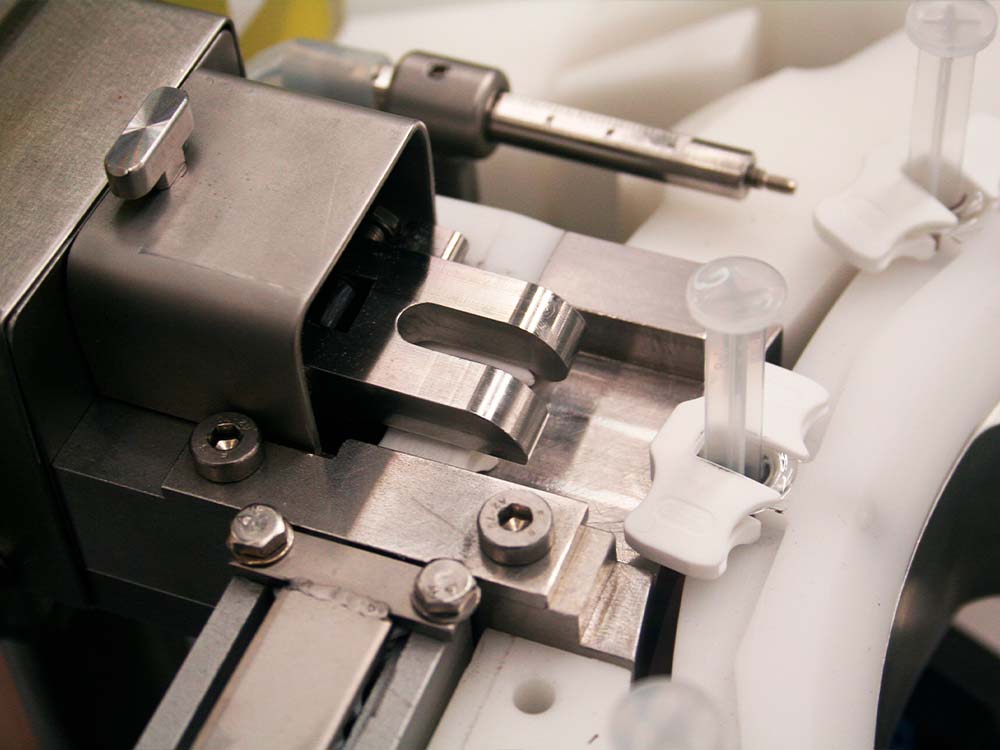

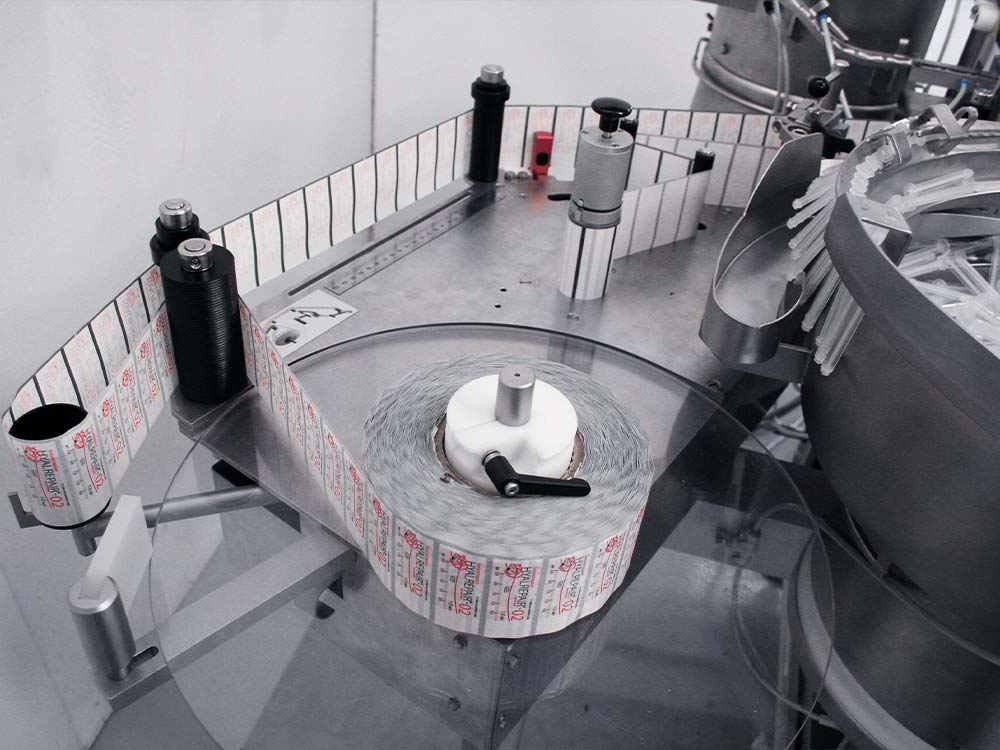

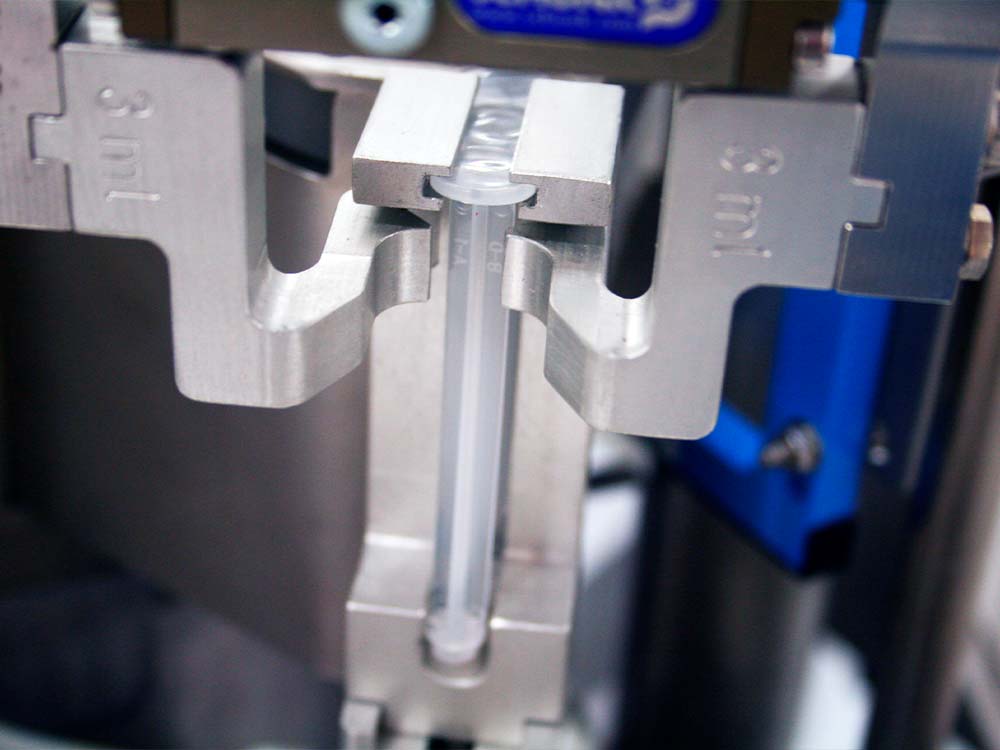

The Type 515 combines high-speed plunger rod insertion and labeling of syringes in one single unit. At the heart of the machine is an automated transport star wheel, which moves product through four different stations, helping assemble up to 40 syringes per minute. At the first station, a pneumatically actuated gripper assembly picks up a plunger rod from the end of the vibratory track and leverages a 2-axis robotic arm to thread it into a syringe. At the second station, backstops are carefully placed on the flange of each syringe. The third and fourth station check for plunger rod and backstop presence.